Industrial vehicles operate in environments that appear controlled but rarely remain predictable. Warehouses, yards, ports, and construction sites rely on routes, rules, and routines to manage movement, yet many serious incidents occur during normal operations rather than exceptional events.

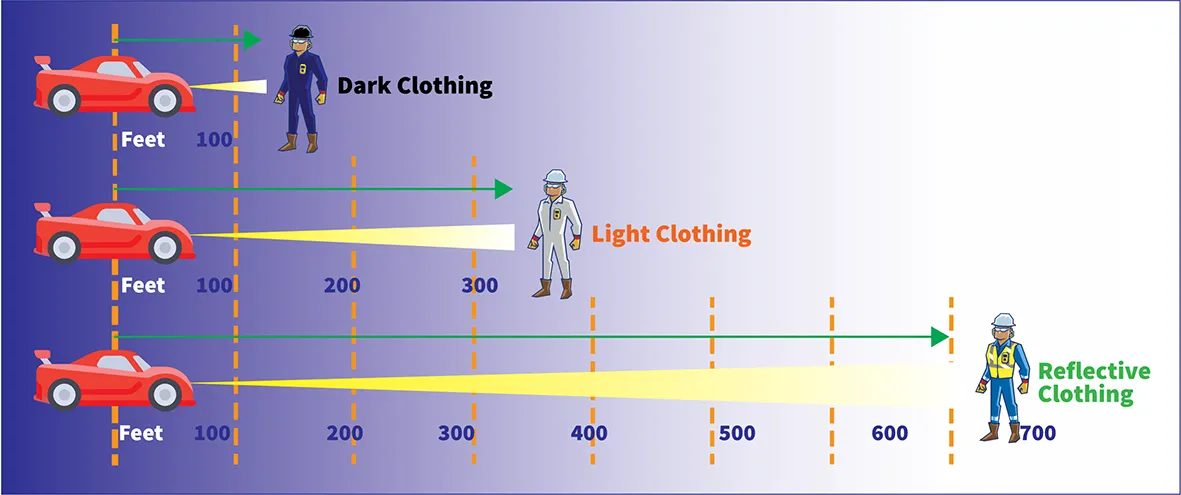

Industrial vehicle safety solutions focus on reducing collision risk by improving visibility, managing blind zones, and aligning safety tools with real operating conditions. This matters because most industrial accidents are not caused by reckless behavior. They occur when people and vehicles fail to see each other early enough to react safely.

Effective safety strategies begin by understanding how and where visibility breaks down before selecting any specific technology.

Why Visibility Is a Core Safety Challenge in Industrial Vehicles

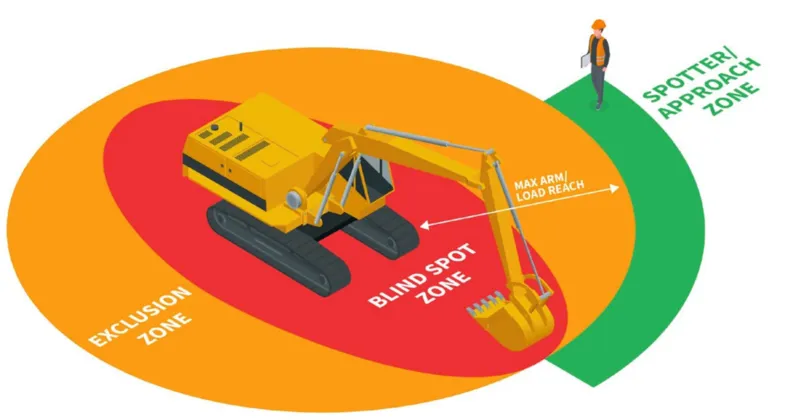

Visibility limitations are inherent to industrial vehicles. Forklifts, yard trucks, loaders, and specialized equipment all place operators inside machines with fixed physical sightlines.

Mirrors, habits, and routine familiarity often compensate for these limits—until conditions change. A pedestrian enters an aisle unexpectedly. A temporary vehicle appears. A load blocks a familiar view. In these moments, reaction time collapses from anticipation to seconds.

Visibility challenges extend beyond rear blind spots. Side zones, ground-level areas, intersections, and reversing paths all contribute to collision risk. Even experienced operators cannot respond to hazards they never see.

This is why visibility is a structural safety challenge rather than a training failure. Rules and signage influence behavior, but they do not alter physical sightlines. When visibility is compromised, risk accumulates quietly during everyday work.

Key Safety Risks Across Industrial Environments

Industrial environments vary widely, but collision risk patterns repeat across sites.

Mixed traffic risk

Pedestrians and vehicles frequently share the same space. Marked walkways reduce exposure, but people still cross wherever movement feels fastest.

Blind zone risk

Racking corners, stacked goods, trailers, and temporary equipment interrupt sightlines. These blind areas shift throughout the day as layouts and workloads change.

Operational disruption risk

After an incident or near miss, operations slow. Confidence drops. Schedules slip. Even minor events can reduce productivity and trust.

Change and variability risk

Rental equipment, seasonal vehicles, and visiting contractors disrupt established movement patterns, reducing the effectiveness of routine-based awareness.

Across environments, these risks share a common cause: operators and pedestrians fail to see each other early enough to react safely.

Why One Safety Solution Does Not Fit All Industrial Vehicles

Industrial vehicles differ in size, duty cycle, operating environment, and installation constraints. A solution that works well for a warehouse forklift may be unsuitable for a yard truck, reach stacker, or mobile crane.

Operating hours vary. Some vehicles run continuously; others operate in short shifts. Installation tolerance also differs. Some fleets can schedule downtime, while others cannot interrupt operations without significant cost.

Environmental conditions further affect suitability. Dust, vibration, weather exposure, and temperature all influence system reliability.

For these reasons, safety solutions must match operational reality. A single, universal approach often leads to poor adoption, unused systems, or operator frustration. The objective is not to add technology, but to reduce risk without disrupting work.

Wired vs. Wireless Camera Systems: Choosing the Right Approach

One common decision point within industrial vehicle safety programs is the choice between wired and wireless camera systems.

Wired camera systems provide stable power, consistent signal quality, and long-term reliability. They are well suited to vehicles with fixed routes, predictable usage, and planned installation windows.

Wireless camera systems reduce installation effort by avoiding long cable runs and drilling. This makes them valuable where downtime must be minimized or vehicle configurations change frequently.

Selection depends on installation tolerance, vehicle usage patterns, and maintenance resources. Fleets prioritizing permanence often favor wired systems, while fleets prioritizing speed and flexibility lean toward wireless solutions.

→ Choosing Between Wired and Wireless Camera Systems for Industrial Vehicles

Wireless Battery Camera Systems for Fast Deployment and Minimal Downtime

Battery-powered wireless camera systems exist to address one specific constraint: installation friction.

By eliminating vehicle power integration and extensive wiring, these systems allow rapid deployment with minimal disruption. In many cases, installation can occur during short maintenance windows or shift changes.

Battery-powered systems are particularly useful where vehicles rotate frequently, layouts change, or pilot deployments are required before committing to permanent installations.

This speed introduces trade-offs. Battery life, charging routines, and signal planning must be managed carefully to avoid coverage gaps.

→ How Industrial Fleets Reduce Installation Downtime with Wireless Battery Camera Systems

Pedestrian Safety Solutions in Warehouse Environments

Warehouses present a concentrated visibility challenge. Forklifts and pedestrians operate in shared, confined spaces throughout the day.

Pedestrian collisions most often occur at intersections, behind loads, near racking corners, and during reversing. In these situations, visibility fails before behavior does.

Camera systems improve safety by making blind zones visible, allowing operators to detect pedestrian movement earlier and respond more smoothly. Pedestrians benefit indirectly as forklift movement becomes more predictable.

This approach does not replace rules or training. It supports them by addressing physical sightline limitations.

→ Reducing Pedestrian Collision Risk in Warehouses with Forklift Camera Systems

Understanding the Limits of Battery-Powered Camera Systems

Battery-powered systems solve installation and flexibility challenges, but they introduce operational limits.

Runtime depends on usage patterns and shift length. Vehicles operating continuously may require frequent charging. Missed charging cycles can lead to visibility gaps.

Wireless performance can be affected by dense metal structures and machinery. Battery systems also require active monitoring and process ownership.

These limitations do not indicate weak technology. They define where the technology fits best.

→ When Battery-Powered Camera Systems Make Sense — and When They Don’t

How to Choose the Right Safety Solution Based on Operational Risk

Effective safety planning begins with risk, not products.

- Map visibility-related risk

- Assess vehicle usage and downtime tolerance

- Evaluate environmental constraints

- Prioritize operator adoption

The most effective solutions reduce risk while fitting daily operational patterns. Complexity without adoption solves nothing.

Frequently Asked Questions About Industrial Vehicle Safety Solutions

What are industrial vehicle safety solutions?

Industrial vehicle safety solutions are systems and strategies designed to reduce collision risk by improving visibility, managing blind zones, and aligning safety tools with real operating conditions.

Are camera systems enough to prevent collisions?

Camera systems improve visibility but are most effective when combined with training, traffic design, and operational rules. They support decision-making rather than replacing it.

Does one safety solution work for all industrial vehicles?

No. Vehicle type, duty cycle, environment, and installation constraints vary widely. Effective safety programs match solutions to specific operational conditions.

How should fleets start improving industrial vehicle safety?

Fleets should begin by identifying visibility-related risks, assessing where collisions are most likely, and selecting solutions that operators will consistently use.

Are wireless or battery-powered systems less reliable?

Not inherently. These systems are effective when used within their intended scenarios. Problems arise when they are applied beyond their operational limits.

Conclusion: Building a Practical Industrial Vehicle Safety Strategy

Industrial vehicle safety improves when visibility aligns with real working conditions. No single solution fits every vehicle or environment.

By understanding visibility limitations, recurring risk patterns, and operational constraints, organizations can build practical safety strategies that reduce collisions without slowing work. This pillar page defines the framework; the supporting cluster articles explore each solution path in depth.